Seamless Laser Micro-cutting Glass MicroLED Substrates

Micron precision cutting

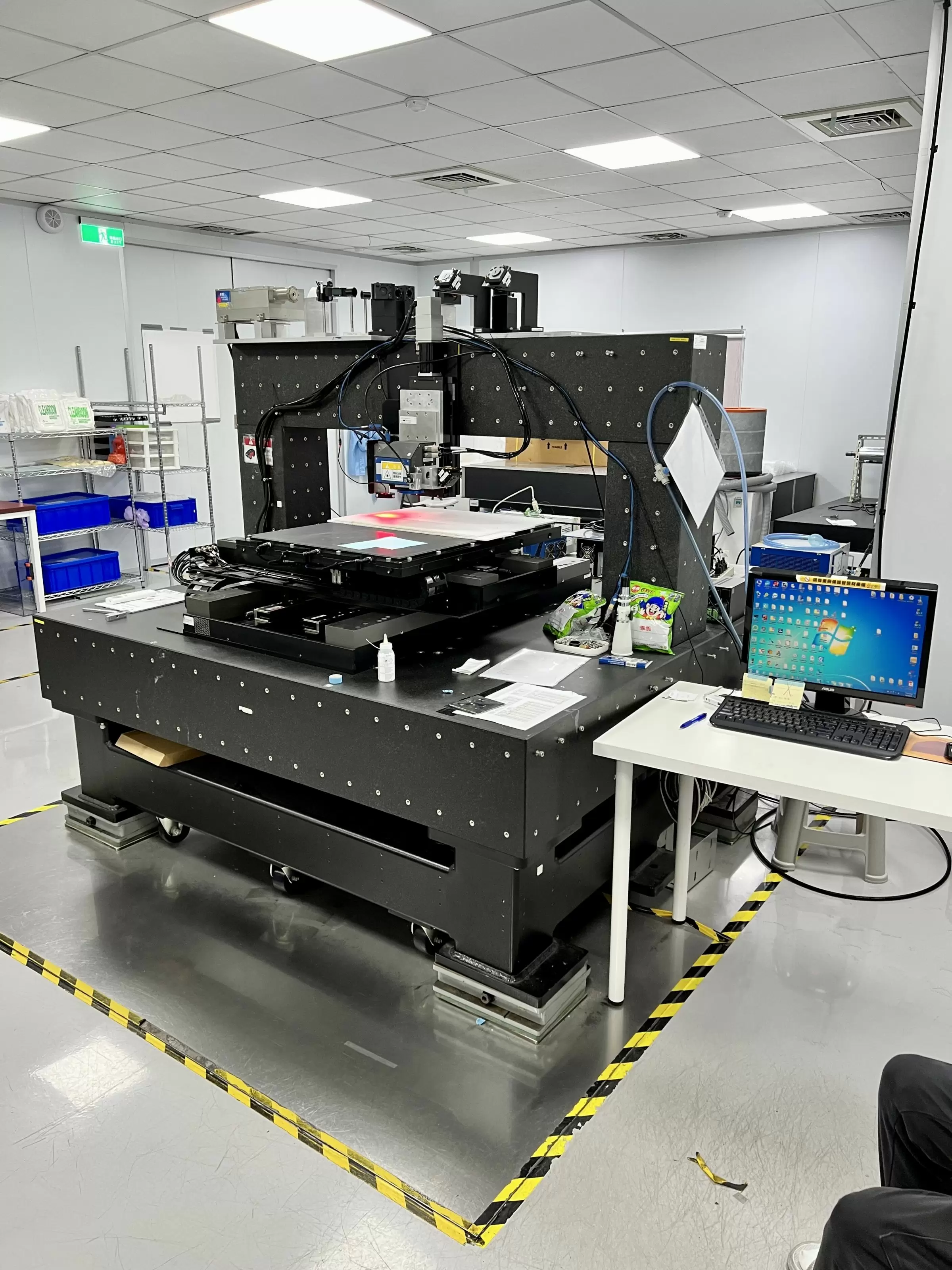

To cut MicroLED glass substrates, Hortech employs micron focused laser beams with a long depth of field that resemble a light knife. The micron groove created by the cutting cannot be distinguished by the naked eye. After cutting the big panels, the small pieces can be combined to produce a continued, seamless large panel.

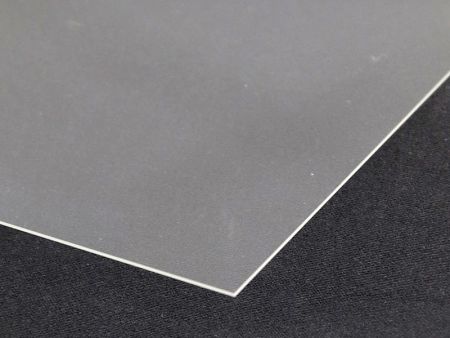

Glass Laser Micro-Cutting

Glass is hard and brittle. It cracks easily. Hence, Hortech employs high-energy focused laser beams with a long depth of field to break the glass from the interior. The cutting does not cause cracks and the precision is very high.

Product Features

- No cracks.

- Micron cutting grooves.

- Micron precision.

Applications

- MicroLED glass cutting.

- Optical glass cutting.

- Optical lens cutting.

- Nozzle cutting.

Seamless Laser Micro-cutting Glass MicroLED Substrates | Laser Engraving & Micro Cutting Machines Manufacturer | Hortech Co.

Located in Taiwan since 2006, Hortech Company has been a manufacturer providing precision laser processing services and custom designed machines. Its core techniques include: Seamless Laser Micro-cutting Glass MicroLED Substrates, laser micro-etching, micro-drilling, micro-cutting, and laser engraving. It has successfully developed products for diverse industries, including optical scales for factory automation and robotics, superfine reticles for the defense industry, and wafer dicing and drilling for the semiconductor industry. Hortech's laser OEM/ODM services have served industrial partners from around the world.

Hortech Company was established by Dr. Owen Chun Hao Li in 2016. It has developed a laser marking system used for the traceability of medical circuit boards for a Taiwanese circuit manufacturer in 2018. It has developed the triple wavelength laser combined machining system for a Singapore manufacturer in 2017. It produced different types of magnetic and optical scales with high accuracy for encoders and actuators since 2019. Hortech kept upgrading its laser machines and expanding its services to different regions. Its rigorous quality control processes ensures its clients' needs are satisfied.

Hortech Co. has been offering customers ultra-precision laser machining services and laser CNC machines since 2006, both with advanced technology and 27 years of experiences, Hortech Co. ensures each customer's demands are met.